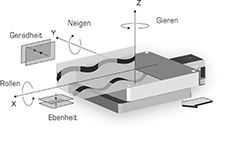

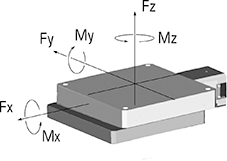

- multi-axis positioning systems possible by simple combination of stages (e.g. with 5104.B20)

- high-precision ball roll spindle (two precision configurations available) or optional smoothed and tempered thread spindle

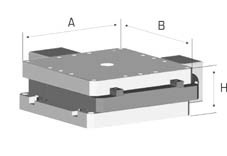

- reduced dimensions due to belt drive

- use of low-friction guides results in optimum fine adjustment due to high reproducibility of minimum system step distance

- 2-phase step motors as standard motorisation (5-phase step motors optional)

- robust surfaces through galvanic anodisation

- two precision configurations